TL101: Transforming FISH Pre-treatment with Automation

Imagine a FISH pre-treatment process that is both efficient and precise, freeing up valuable time and resources while ensuring consistently reliable results. This is the reality with the innovative TL101 Fully Automatic FISH Pre-treatment System, a revolutionary instrument that is revolutionizing the field of histopathology.

Unveiling the Cutting-edge Fully Automatic FISH Pre-treatment System

Introduction:

Introducing the Fully Automatic FISH Pre-treatment System, a technological breakthrough in pathology designed to revolutionize Fluorescence In Situ Hybridization (FISH) detection. Developed independently, this innovative instrument eliminates traditional manual methods, offering an automated and standardized approach to pre-treating paraffin sections (formalin-fixed paraffin-embedded - FFPE) for accurate nucleic acid detection in tissue samples.

Key Features:

- Enhancing FISH Quality Detection:

- Fully automated wax removal and enzymatic digestion for FISH pre-treatment.

- Unique design accommodating various sample types for enhanced flexibility.

- Substantially reduces manual operation errors.

- Markedly improves the success rate of FISH probes hybridization.

- Simplifying FISH Detection:

- Complete replacement of manual pre-treatment, facilitating easy learning.

- Standardized FISH detection processes for enhanced consistency.

- Simplifies laboratory quality control for FISH testing.

- Optimizing Efficiency and Resource Utilization:

- Achieves a hybridization success rate exceeding 95% post-sample processing.

- Reduces duplicate detection rates and minimizes FISH probe consumption.

- User-friendly interface for efficient, time-saving, and labor-saving operations.

Benefits for Clinical and Medical Laboratories:

The Fully Automatic FISH Pre-treatment System delivers significant value to clinical and medical laboratories:

- Quality Enhancement: Elevates the overall quality of FISH detection through precise and automated pre-treatment steps, minimizing errors, and increasing the success rate of probe hybridization.

- Operational Simplification: Simplifies the FISH detection process by replacing manual pre-treatment with an automated system, reducing operational complexities and enhancing standardization.

- Efficiency and Cost Reduction: Optimizes resource utilization by minimizing duplicate detection rates and reducing FISH probe consumption, ultimately enhancing efficiency and lowering operational costs.

In essence, the Fully Automatic FISH Pre-treatment System redefines the landscape of FISH detection, providing laboratories with a reliable, efficient, and standardized solution for qualitative and quantitative nucleic acid detection in tissue samples.

TL101: Revolutionizing FISH Pre-treatment with Automation and Precision

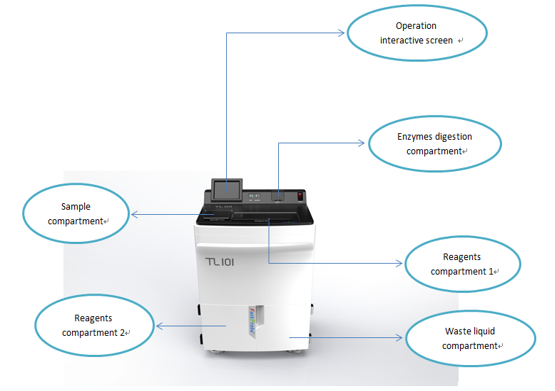

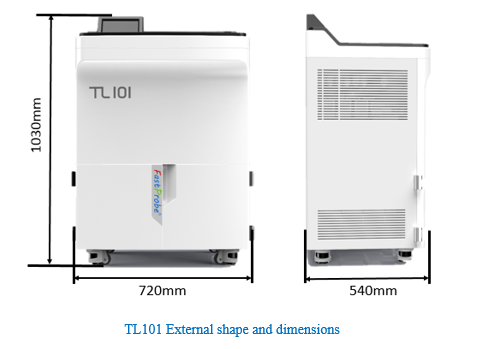

The TL101 Fully Automatic FISH Pre-treatment System represents a significant advancement in the field of histopathology. Developed by Wuhan HealthCare Biotechnology Co., Ltd., this innovative instrument automates and standardizes the entire FISH pre-treatment process, paving the way for enhanced quality, reproducibility, and efficiency in FISH analysis.

Prior to the TL101, FISH pre-treatment was a manual, labor-intensive process. This often led to inconsistencies and variability in results, impacting the reliability and accuracy of FISH analysis. The TL101 eliminates these challenges by automating each crucial step:

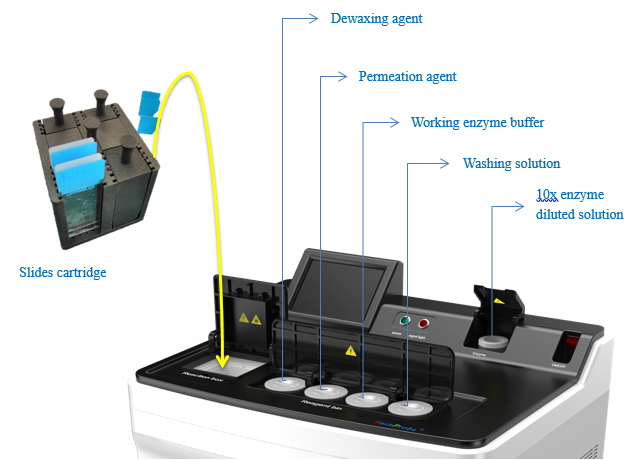

- Deparaffinization: Removal of paraffin wax embedding tissues.

- Rehydration: Restoration of tissue water content.

- Heat treatment: Denaturation of DNA and RNA.

- Proteolysis: Removal of proteins masking target antigens.

- Rinsing: Removal of residual reagents.

- Dehydration: Preparation of tissues for hybridization.

The TL101 boasts several key advantages:

- Enhanced Quality and Reproducibility: Consistent and standardized pre-treatment ensures reliable and reproducible FISH results.

- Improved Efficiency: Automated processing significantly reduces hands-on time, freeing up valuable laboratory resources.

- Reduced Errors: Automation minimizes the risk of human error associated with manual handling.

- Enhanced Safety: Automated handling minimizes exposure to hazardous chemicals.

- Increased Throughput: The TL101 can process up to 12 slides simultaneously, increasing laboratory productivity.

- Simplified Workflow: Pre-programmed protocols for various tissues and protocols simplify operation.

- User-friendly Interface: Intuitive interface facilitates easy operation and minimal training requirements.

Overall, the TL101 Fully Automatic FISH Pre-treatment System represents a game-changer for histopathology laboratories. By automating and standardizing the FISH pre-treatment process, the TL101 delivers:

- Improved data quality: Reliable and reproducible results drive accurate diagnoses.

- Enhanced efficiency: Increased throughput and reduced processing time.

- Simplified workflow: User-friendly interface and pre-programmed protocols.

- Reduced labor costs: Automation minimizes hands-on time.

The TL101 is a valuable investment for any laboratory seeking to:

- Improve the quality and accuracy of FISH analysis.

- Increase efficiency and productivity.

- Reduce labor costs and optimize workflow.

With its advanced technology and user-friendly design, the TL101 fully automates the FISH pre-treatment process, empowering histopathology laboratories to achieve superior results and enhance patient care.

Prior to the TL101, FISH pre-treatment was a laborious manual process, prone to inconsistencies and variability that could impact the accuracy of FISH analysis. The TL101 tackles these challenges head-on by automating every crucial step of the pre-treatment process, including:

- Deparaffinization: Removal of paraffin wax from tissue samples.

- Rehydration: Restoration of tissue water content for optimal analysis.

- Heat treatment: Denaturation of nucleic acids for improved accessibility.

- Proteolysis: Removal of proteins masking target antigens for specific probe binding.

- Rinsing: Removal of residual reagents for accurate results.

- Dehydration: Preparation of tissues for hybridization and analysis.

The TL101 offers several key advantages that empower histopathology laboratories:

- Enhanced Quality and Reproducibility: Consistent and standardized pre-treatment delivers reliable and reproducible FISH results, boosting diagnostic confidence.

- Unmatched Efficiency: Automated processing significantly reduces hands-on time, freeing up valuable laboratory resources for other tasks.

- Reduced Errors: Automation minimizes human error associated with manual handling, ensuring data integrity.

- Enhanced Safety: Automated reagent handling minimizes exposure to hazardous chemicals, protecting laboratory personnel.

- Increased Throughput: Simultaneous processing of up to 12 slides significantly increases laboratory productivity.

- Simplified Workflow: Pre-programmed protocols for various tissues and FISH protocols streamline operation and training.

- User-friendly Interface: Intuitive design facilitates easy operation, minimizing the need for extensive training.

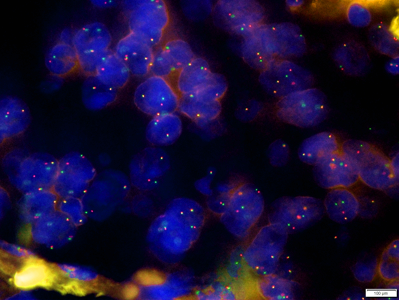

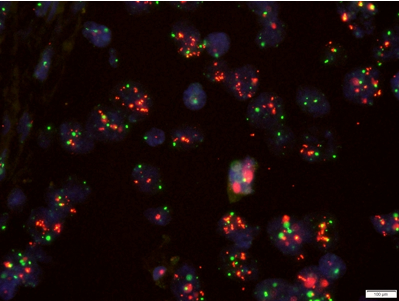

Positive ALK

Positive HER-2

The TL101 Fully Automatic FISH Pre-treatment System is more than just an instrument; it represents a paradigm shift in FISH pre-treatment. By automating and standardizing the process, the TL101 empowers histopathology laboratories to:

- Achieve superior data quality: Reliable and reproducible results lead to more accurate diagnoses.

- Optimize workflow and resources: Increased throughput and reduced hands-on time allow for improved efficiency.

- Embrace a user-friendly experience: Intuitive interface and pre-programmed protocols simplify operation and training.

- Reduce labor costs: Automation minimizes hands-on time and associated costs.

The TL101 is a valuable investment for any laboratory seeking to:

- Elevate FISH pre-treatment standards.

- Enhance efficiency and productivity.

- Reduce labor costs and optimize workflow.

- Deliver superior patient care.

With its cutting-edge technology and user-friendly design, the TL101 Fully Automatic FISH Pre-treatment System is paving the way for a new era in histopathology. By automating and standardizing FISH pre-treatment, the TL101 empowers laboratories to achieve superior results, enhance patient care, and ultimately contribute to advancements in medical research.

The Evolution of FISH Pretreatment : A Comparison of Traditional and Automated FISH Pretreatment

For decades, the success of FISH analysis relied on a meticulous, time-consuming manual pre-treatment process. This method, while offering flexibility and control, suffered from inconsistencies and human error, impacting the reliability of results. Today, automated FISH pre-treatment systems like the Fully Automatic FISH Pretreatment System (FAFPS) are revolutionizing the field, offering a transformative alternative.

Traditional manual processing involves long hours of hand-on manipulation and reagent application. The FAFPS automates each crucial step, from deparaffinization to dehydration, liberating valuable lab resources for other tasks and minimizing human error. This automation ensures consistency and significantly improves data quality, leading to greater confidence in diagnoses and scientific research.

The FAFPS also boasts unmatched efficiency. Processing up to 12 slides simultaneously, it dramatically increases throughput compared to single-slide manual methods. This translates to faster turnaround times, benefiting patient care and research efforts.

Moreover, the FAFPS prioritizes laboratory safety by minimizing exposure to harsh chemicals. This enhanced safety further reinforces its value as a responsible and sustainable choice for modern labs.

While the initial cost of the FAFPS may be higher, long-term benefits outweigh the investment. Improved workflow efficiency, reduced labor costs, and enhanced data quality contribute to significant cost savings. Additionally, the user-friendly interface minimizes training requirements, allowing for seamless integration into existing workflows.

In conclusion, automated FISH pre-treatment systems like the FAFPS represent a paradigm shift in the field. By automating and standardizing the process, they deliver unparalleled efficiency, consistency, and data quality, empowering laboratories to achieve a new standard of excellence in FISH analysis. This innovative technology paves the way for a future of enhanced patient care and scientific discovery.

Unveiling the Power of Centrifugation: A Revolution in Scientific and Industrial Separation

Introduction:

Centrifugation, a process harnessing the formidable force of centrifugal acceleration, has become a cornerstone in scientific, medical, and industrial endeavors. This innovative technique has revolutionized the way we separate and analyze substances based on their density. In this exploration, we delve into the inner workings of centrifuges and their diverse applications that span across multiple disciplines.

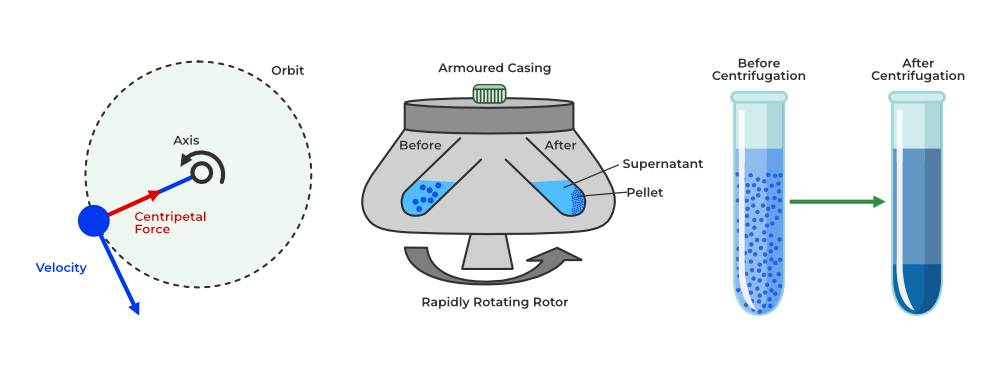

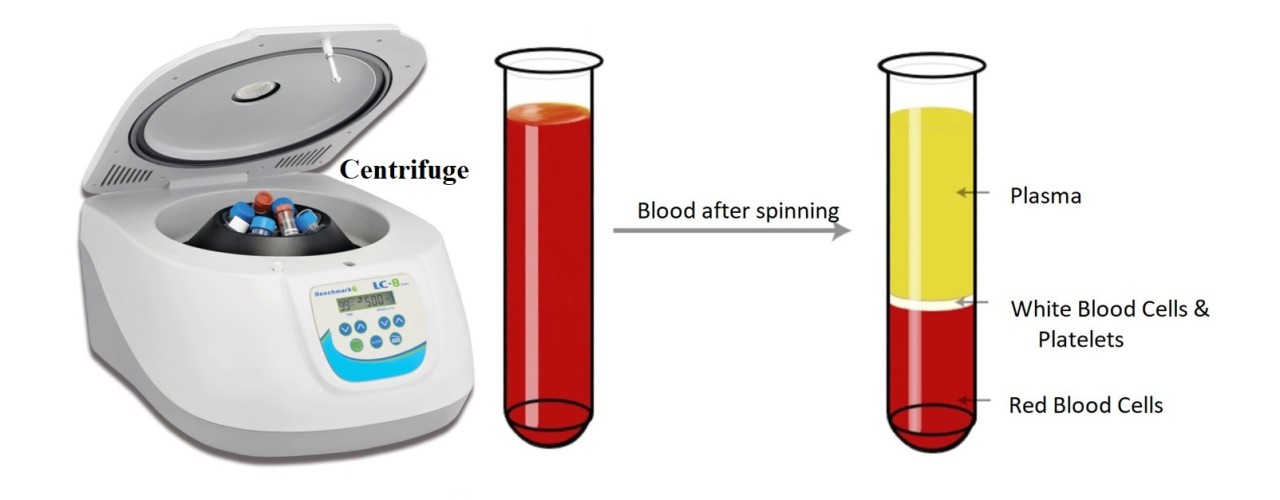

The Centrifuge Principle:

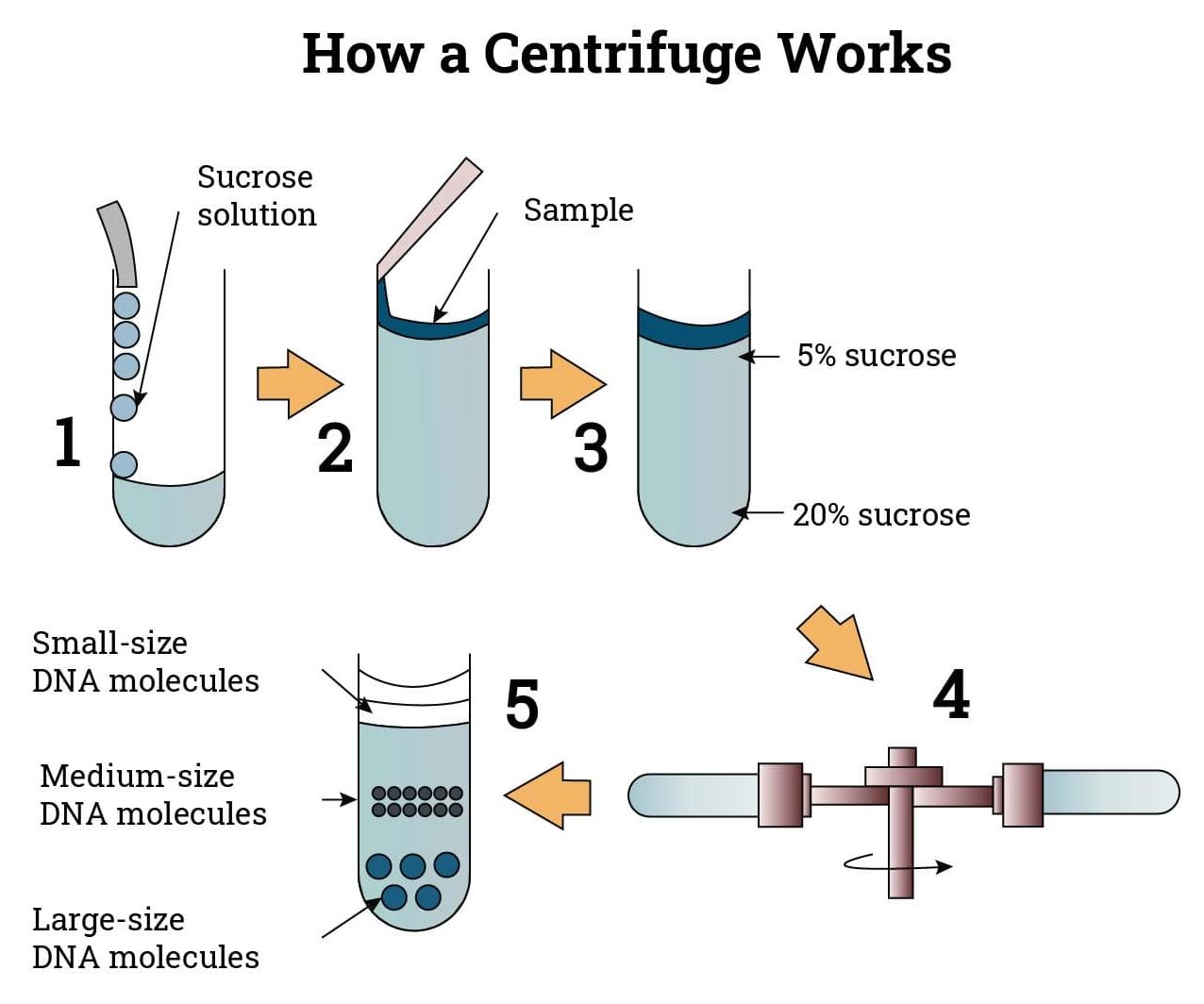

At its core, a centrifuge relies on the principle of centrifugal force. When a sample is rapidly spun, the denser components migrate outward while the lighter components move towards the center. This physical phenomenon allows for the efficient separation of diverse mixtures, ranging from biological samples to industrial solutions.

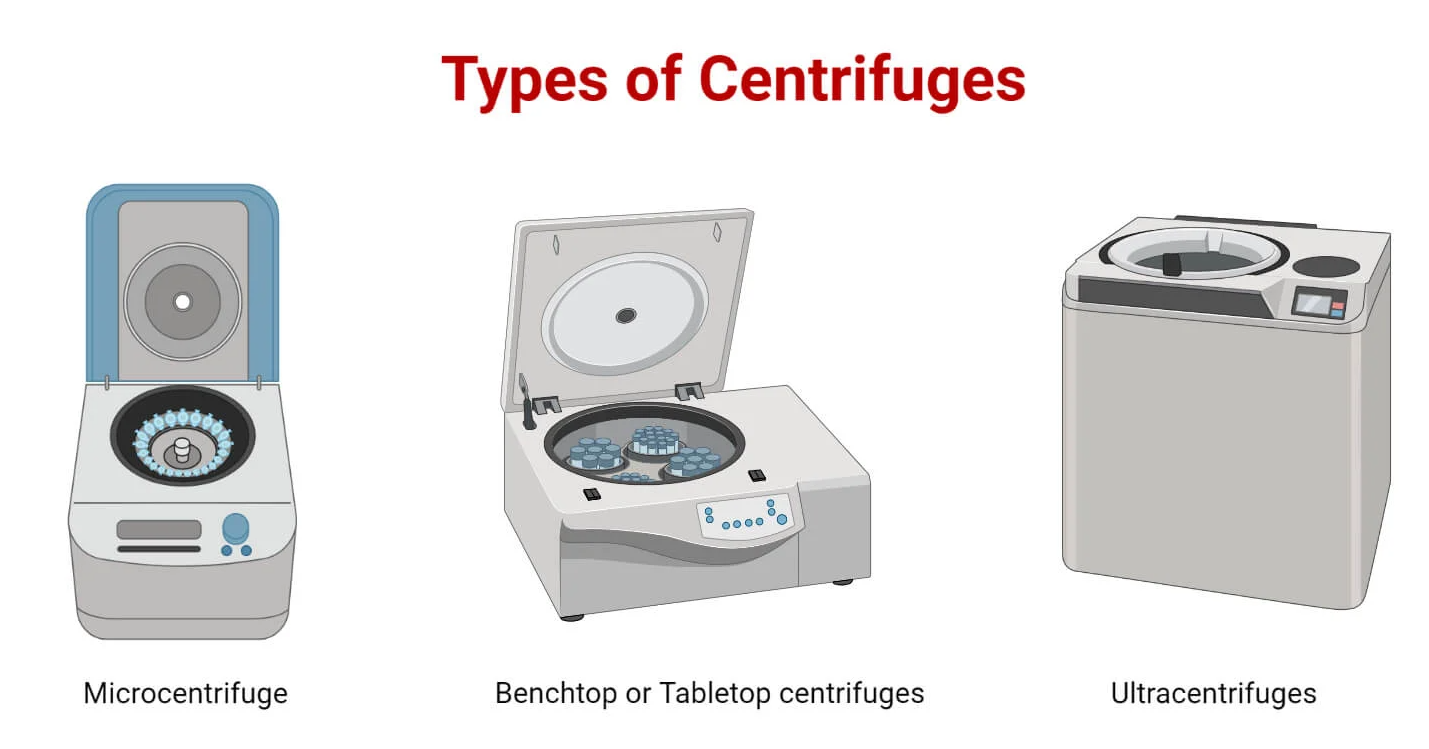

Types of Centrifuges:

Centrifuges come in various forms, each tailored to specific applications. Microcentrifuges are adept at handling small volumes, making them ideal for molecular biology research. Ultracentrifuges, on the other hand, reach extraordinary speeds, enabling the separation of particles at the molecular level. Refrigerated centrifuges maintain low temperatures during operation, crucial for preserving sample integrity.

Biomedical Applications:

In the realm of medicine and biology, centrifugation plays a pivotal role. Blood samples can be fractionated into red blood cells, white blood cells, and plasma, allowing for diagnostic insights. Cellular organelles and proteins are meticulously separated, facilitating advanced research in molecular biology. The centrifuge has become an indispensable tool in laboratories worldwide, shaping advancements in medical science.

Industrial and Chemical Processes:

Beyond the laboratory, centrifuges find extensive use in industrial and chemical settings. From separating oil and water in petroleum refining to purifying chemicals in manufacturing processes, centrifugation enhances efficiency and precision. Its applications extend to wastewater treatment, pharmaceutical production, and the food and beverage industry, illustrating the versatility of this technology.

Technological Advancements:

Continual advancements in centrifuge technology have further expanded its capabilities. Automated systems, integrated with sophisticated control mechanisms, enhance precision and reproducibility. Modern centrifuges are designed with user-friendly interfaces, making them accessible to a broader audience and streamlining complex separation protocols.

Conclusion:

The centrifuge stands as a testament to human ingenuity, transforming the way we approach separation and analysis in diverse fields. From fundamental research in molecular biology to optimizing industrial processes, the centrifuge's impact reverberates across the scientific landscape. As technology evolves, so too will the capabilities of centrifugation, promising continued breakthroughs in understanding and manipulating matter at the microscopic level.